Normally Open Push Button Working Principle and Application | HBAN Push button

Normally Open Push Button Explained

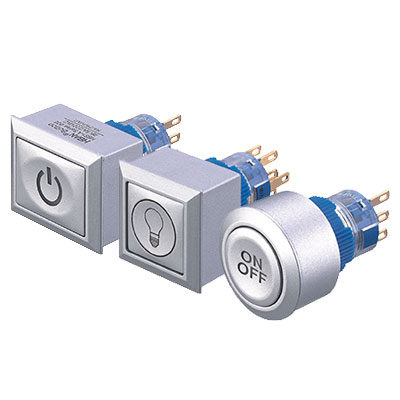

Normally open (NO) pushbutton switches are vital control elements in electrical and electronic systems. Whether you need to start industrial machinery, control an automated process, or enable user interaction in consumer electronics, understanding and selecting the right normally open pushbutton is critical. Are you looking for high-quality, reliable and durable pushbutton switches, signal lights or emergency stop buttons?

In their quiescent state, normally open push buttons maintain an open circuit, characterized by a high impedance path that prevents the flow of electrical current. This default condition ensures that the circuit remains inactive until a deliberate action is taken. Upon actuation, the applied mechanical force overcomes the internal spring tension, causing conductive contacts within the switch to engage. This action establishes a low-impedance pathway, allowing current to flow and energize the intended circuit.

The versatility of normally open push buttons is evident in their widespread adoption across diverse applications, ranging from heavy industrial machinery and automated production lines to consumer electronics and sophisticated control panels. Their inherent simplicity facilitates seamless integration into various designs, providing a reliable and intuiitive means of control.

Moreover, normally open push buttons play a critical role in enhancing safety and operational integrity within systems. They are commonly employed in safety circuits, alarm systems, and emergency stop mechanisms, providing a dependable means to initiate actions or interrupt potentially hazardous processes only when intentionally activated. This deliberate control minimizes the risk of accidental or unintended system activation.

Understanding Normally Open Push Button Functionality

Normally open push buttons are indispensable components in electrical circuits, serving as essential control elements for a broad array of devices, including machinery, lighting systems, and electronic equipment. In their unactuated state, these buttons exhibit an "open" configuration, effectively isolating the downstream circuit and preventing the flow of electrical current. This open state represents the button's default condition.

The activation of a normally open push button is achieved through the application of mechanical pressure. This pressure forces the internal contacts of the switch to close, creating a conductive path that allows electrical current to pass through the circuit. This seemingly simple action can initiate a wide range of responses, from energizing a light source to activating a complex motor sequence. Upon the removal of the actuating force, the button's internal return mechanism, typically a spring, returns the contacts to their original open position. This action interrupts the flow of electrical current, effectively de-energizing the circuit. As a professional manufacturer of push button switches, signal lights and emergency stop buttons, HBAN brand is committed to providing products with excellent performance, safety and reliability to meet your diverse needs.

The widespread utility of normally open push buttons is further enhanced by their availability in a variety of designs, sizes, and configurations. This versatility allows for seamless integration into diverse applications and operating environments. Many designs incorporate tactile feedback mechanisms, such as a distinct "click," to provide users with positive confirmation of switch actuation. This tactile response enhances the user experience and ensures reliable operation.

The straightforward design and reliable operation of normally open push buttons make them a preferred choice in control panels, machinery interfaces, and other applications where direct and dependable user input is paramount. A fundamental understanding of their operating principles is therefore essential for anyone involved in electrical engineering, automation, or system design.

How Normally Open Buttons Work

A normally open push button comprises the following key components:

- Actuator: The external component that the user manipulates (typically by pressing) to initiate the switch action.

- Internal Contacts: The conductive elements within the switch that establish or interrupt the electrical path. These consist of:

- Fixed Contact(s): Stationary conductive element(s).

- Movable Contact(s): Conductive element(s) that change position in response to actuator movement.

- Return Mechanism: A component, most commonly a spring, that provides the force necessary to return the actuator and movable contact(s) to their default (unactuated) position.

In the unactuated state, with no external force applied to the actuator, the movable contact is physically separated from the fixed contact. This separation creates an open circuit, characterized by a theoretically infinite resistance, which effectively prevents the flow of electrical current.

When a user applies pressure to the actuator, the following sequence of events occurs:

- The actuator begins to move.

- This movement forces the movable contact to displace.

- The movable contact is brought into physical contact with the fixed contact.

- This contact between the conductive elements establishes a low-resistance path, completing the electrical circuit and allowing current to flow.

Upon the release of the actuating force, the return mechanism (spring) exerts a force that:

- Returns the actuator to its original position.

- Causes the movable contact to disengage from the fixed contact.

- This disengagement re-establishes the open circuit condition, interrupting the flow of electrical current.

Electrical States:

- Open State: Characterized by extremely high electrical resistance (approaching infinity) and negligible current flow. This is the default, unactuated state of a normally open push button.

- Closed State: Characterized by significantly reduced electrical resistance, allowing current to flow through the circuit. This state is achieved only while the actuator is depressed.

Common Applications of Normally Open Push Buttons

Normally open push buttons find extensive use in a wide array of electrical and electronic systems, primarily for initiating or triggering specific functions. Their ability to provide reliable, momentary control makes them indispensable in numerous applications. Here are some common examples:

Industrial Field:

- Machine Start/Stop: Controlling the activation and deactivation of motors, pumps, and other industrial equipment.

- Jog Control: Enabling the incremental movement of machinery for precise positioning or setup operations.

- Emergency Stop (in conjunction with NC): Used in conjunction with normally closed buttons to provide redundant emergency shutdown capabilities.

- Enable Functions: Activating or deactivating specific machine functions or modes of operation.

- Limit Switches (sometimes NO): Detecting the presence or position of mechanical components, often used in safety or control systems.

Automation Field:

- PLC Input: Providing discrete input signals to programmable logic controllers (PLCs) for automated control sequences.

- Human-Machine Interface (HMI): Serving as input devices on operator panels, allowing users to interact with and control automated systems.

- Sensor Activation: Triggering data acquisition or control actions in response to sensor inputs.

Commercial Field:

- Elevator Buttons: Requesting specific floor destinations in elevator systems.

- Control Panels: Providing user interface elements for various commercial equipment and systems.

- Ticketing Machines: Enabling users to select options and initiate ticket dispensing.

Consumer Electronics Field:

- Power Buttons (momentary): Initiating the power-on sequence for electronic devices.

- Selection Buttons: Navigating menus and selecting options on electronic devices.

- Reset Switches: Initiating a system reset or restart procedure.

Normally open buttons are widely used in industries such as industry, automation, commerce and consumer electronics, playing an important role in control and safety. HBAN has a comprehensive product line of push button switches, signal lights and emergency stop buttons, which can provide ideal solutions for your various application scenarios. If you have any needs regarding product selection or customization, please feel free to contact us, our professional team will serve you wholeheartedly.

Advantages of Using Normally Open Buttons

Normally open push buttons offer several distinct advantages due to their inherent operating characteristics:

- Safety: In many applications, they provide a degree of fail-safe operation. The default open state prevents accidental energization of the circuit, reducing the risk of unintended activation of connected devices or machinery.

- Controllability: They offer precise, user-controlled activation of electrical circuits, allowing for deliberate and intentional initiation of desired functions.

- Reliability: Their relatively simple mechanical design contributes to high operational reliability and a long service life, even under demanding conditions.

- Cost-Effectiveness: For applications requiring momentary switching or pulsed control, they often represent a cost-effective solution compared to more complex switching mechanisms.

Considerations for Purchasers:

Normally open push buttons offer a combination of long-term reliability, a reduced risk of accidental activation, and cost-effectiveness, making them a desirable choice for many applications.

Wiring Diagrams for Normally Open Push Buttons

Wiring a normally open push button is generally straightforward. Here are some basic wiring configurations:

- Basic Circuit: A simple circuit consisting of a power source, a normally open push button, and a load (such as a lamp, relay, or other electrical device). The button is connected in series with the load, allowing it to control the flow of current.

- Control Circuit: Using a normally open push button as an input device for a relay or a programmable logic controller (PLC). The button's activation triggers the relay or PLC input, which in turn controls other devices or processes.

- Safety Circuit: Incorporating a normally open push button into a safety interlock circuit. This configuration ensures that a specific condition must be met (i.e., the button must be pressed) before a potentially hazardous operation can be initiated.

Terminal Markings:

Normally open push buttons are typically equipped with terminals designated as "NO" (normally open) and "COM" (common). The "COM" terminal serves as the common connection point, while the "NO" terminal is the output terminal that becomes connected to the common terminal when the button is pressed.

Comparison Between Normally Open and Normally Closed

Normally open (NO) and normally closed (NC) push buttons represent the two fundamental configurations of switch contacts, distinguished by their default states:

- Normally Open (NO): In its default state, the circuit is open (non-conducting), and current flow is inhibited. The circuit is closed (conducting) only when the button is actively pressed.

- Normally Closed (NC): In its default state, the circuit is closed (conducting), and current flows freely. The circuit is opened (non-conducting) only when the button is actively pressed.

Application-Specific Guidance:

- Normally Open (NO): Best suited for applications where a circuit needs to be energized or an action needs to be initiated by a deliberate user action. Common uses include:

- Starting motors or machinery

- Activating signaling devices (e.g., horns, buzzers)

- Sending a pulse to a logic controller

- Normally Closed (NC): Typically employed in applications where a circuit is normally energized and needs to be de-energized or interrupted by a user action or a specific event. Common uses include:

- Emergency stop buttons

- Safety interlocks

- Limit switches

- Sensors that trigger an action when a condition is met (e.g., a door closing)

Fail-Safe Considerations:

In safety-critical applications, such as emergency stop circuits, normally closed (NC) buttons are often preferred. This is because an NC configuration can provide a degree of fail-safe operation. For example, if the wiring to an NC button is damaged or disconnected, the circuit will be interrupted, which can trigger the intended safety response (e.g., shutting down a machine). In contrast, a broken wire in a circuit with a normally open (NO) button might go undetected, potentially preventing the button from functioning in an emergency.

Choosing the Right Normally Open Push Button

Selecting the appropriate normally open push button is crucial for ensuring the reliability, performance, and longevity of the system in which it is integrated. Several key selection criteria must be carefully considered:

- Electrical Ratings: The voltage and current ratings of the push button must be compatible with the electrical characteristics of the circuit it will control. Exceeding these ratings can lead to switch failure, overheating, or damage to other components.

- Contact Material: The material of the electrical contacts within the switch significantly affects its performance and reliability. Common contact materials include:

- Silver: Offers good conductivity and is suitable for general-purpose applications.

- Gold: Provides excellent corrosion resistance and is ideal for low-current or low-voltage applications where signal integrity is critical.

- Mechanical Specifications: These specifications define the physical characteristics and performance of the push button, including:

- Actuation Force: The amount of force required to depress the button.

- Travel: The distance the button moves when pressed.

- Lifespan: The number of mechanical cycles (presses) the button is designed to withstand.

- Environmental Factors: The operating environment can significantly impact the performance and reliability of a push button. Important factors to consider include:

- IP Rating: A measure of the switch's protection against dust and moisture ingress.

- Operating Temperature Range: The range of temperatures within which the switch can operate reliably.

- Mounting Style: Push buttons can be mounted in various ways, including:

- Panel Mount: Designed to be mounted through a hole in a panel or enclosure.

- PCB Mount: Designed to be mounted directly onto a printed circuit board.

- Standards and Certifications: Compliance with relevant industry standards and certifications (such as UL, CE, and RoHS) ensures that the push button meets specific safety, performance, and environmental requirements.

Choosing the right normally open button requires comprehensive consideration of electrical parameters, contact materials, mechanical life, environmental factors, and installation methods. If you have any questions about how to choose the right push button switch, or want to learn more about HBAN brand push button switches, signal lights, and emergency stop buttons, please contact us now! You can send an email to hb@hban.cc to leave a message. Looking forward to working with you!

Considerations for Purchasers:

For purchasers, key considerations include:

- Reliability: Selecting a reputable manufacturer and a robust design to ensure long-term, trouble-free operation.

- Cost-Effectiveness: Balancing performance requirements with budgetary constraints to achieve the optimal value proposition.

- Compliance: Verifying that the push button complies with all applicable industry standards and regulations to ensure safety and legal compliance.

In summary, normally open push button switches play an important role in various electrical and electronic systems. Selecting high-quality, reliable push buttons is essential to ensure the stable operation of the system. HBAN brand is your trusted partner with its excellent product quality and professional service. Click Contact Us to send your inquiry. We look forward to hearing from you!

HB-TS Series Touch Switch Product Introduction | HBAN Push button

HB-TS Series Touch Switch Product Introduction | HBAN Push button

HBPS series Piezoelectric switch Product Introduction | HBAN Push button

HBPS series Piezoelectric switch Product Introduction | HBAN Push button

HBS1-D series push button switch Product Introduction | HBAN Push button

HBS1-D series push button switch Product Introduction | HBAN Push button

HB-K10 HB-K20 Series Product Introduction | HBAN Push button

HB-K10 HB-K20 Series Product Introduction | HBAN Push button